How to Buy Low Volume and Precise Injection Molding from China

In today’s competitive global market, many companies look to China for affordable and high-quality injection molding services. This is especially true for those seeking low volume injection molding and precise injection molding solutions. By leveraging China’s extensive manufacturing capabilities, businesses can benefit from cost-effective production without compromising on quality. In this guide, we’ll explore how to effectively purchase these services from China.

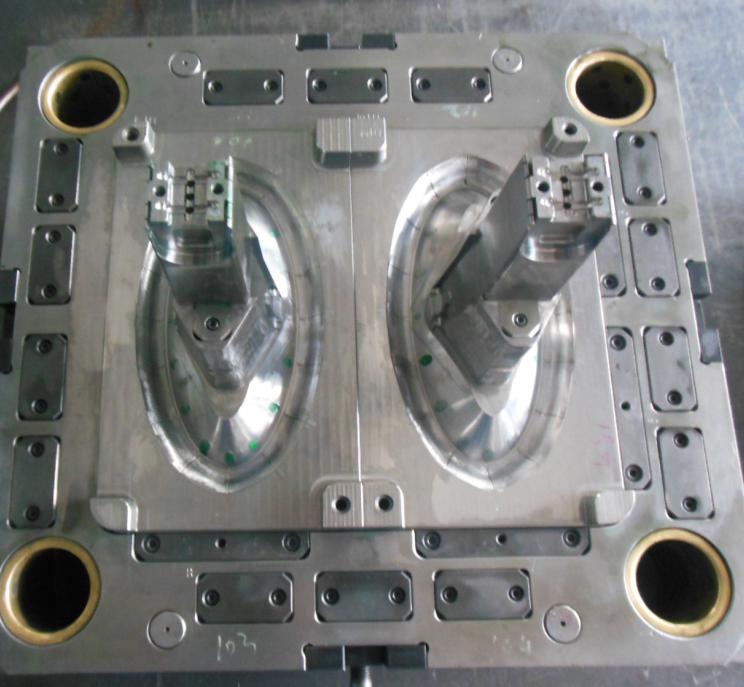

Understanding Injection Molding in China

What is Low Volume Injection Molding?

Low volume injection molding is ideal for companies needing small quantities of plastic parts. This approach reduces costs and speeds up the product development cycle. It’s perfect for prototypes, pilot runs, or products with limited demand.

Why Opt for Precise Injection Molding?

Precise injection molding focuses on producing parts with tight tolerances and complex geometries. It is crucial for industries requiring accuracy, such as medical devices or automotive components.

Advantages of Sourcing from China

- Cost Efficiency: Lower labor and production costs translate into competitive pricing.

- Advanced Technology: Many Chinese manufacturers invest in cutting-edge technology and equipment.

- Skilled Workforce: A large, skilled labor pool ensures high-quality production.

- Scalability: Chinese factories can handle both small and large volume orders with ease.

Steps to Buy Low Volume and Precise Injection Molding from China

Step 1: Define Your Requirements

Clearly outline your project specifications. Determine whether you need low volume or precise injection molding, or both. Detail the materials, dimensions, tolerances, and expected turnaround times.

Step 2: Research Potential Manufacturers

Use online platforms and industry connections to find reputable Chinese manufacturers. Look for companies with experience in low volume injection molding and precise injection molding. Reading reviews and seeking recommendations can provide valuable insights.

Step 3: Assess Capabilities

Request detailed information on each manufacturer’s capabilities. Ensure they have experience with your specific industry needs. Ask about their machinery, quality control processes, and compliance with international standards.

Step 4: Request Quotations

Contact multiple manufacturers to request quotes. Provide detailed information to receive accurate estimates. Compare pricing, turnaround times, and other factors relevant to your decision-making process.

Step 5: Evaluate Quality Assurance

Quality control is critical in injection molding. Verify that the manufacturer employs robust quality assurance processes. This includes certifications like ISO 9001 and the use of high-quality materials.

Step 6: Visit the Facility

If possible, visit the manufacturing facility in China. This allows you to evaluate their operations directly, ensuring they meet your standards for quality and efficiency.

Step 7: Request Samples

Before committing to a full production run, request samples of your product. This allows you to assess the quality and precision of the manufacturer’s work.

Step 8: Negotiate Terms

Once satisfied with a manufacturer’s capabilities and sample quality, negotiate terms. This includes pricing, lead times, payment terms, and delivery schedules.

Step 9: Monitor Production

Maintain regular communication with the manufacturer during production. Regular updates and quality checks help ensure everything is on track.

Step 10: Evaluate the Final Product

Upon receiving your order, thoroughly evaluate the products to ensure they meet your specifications. Address any discrepancies promptly.

Table: Comparison of Injection Molding Services in China

| Aspect | Low Volume Injection Molding | Precise Injection Molding |

|---|---|---|

| Ideal for | Prototyping, small batches | Complex, high-tolerance parts |

| Cost | Lower initial investment | Potentially higher due to precision |

| Turnaround Time | Faster setup, shorter runs | Varies based on complexity |

| Applications | Consumer products, start-ups | Medical, automotive, aerospace |

| Key Benefit | Cost-effective small runs | Accuracy and precision |

Tips for Successful Engagement with Chinese Manufacturers

Build Strong Relationships

Establishing a good relationship with your manufacturer can lead to better communication and flexibility. Consider the cultural nuances and engage with respect and understanding.

Utilize Contracts

Use clear, detailed contracts to outline every aspect of the project. This protects both parties and sets clear expectations for production quality and delivery times.

Embrace Technology

Leverage technology to maintain good communication with your manufacturer. Video calls, emails, and instant messaging can help manage expectations and address issues swiftly.

Challenges and How to Overcome Them

Language Barrier

While many Chinese manufacturers have English-speaking staff, miscommunications can occur. Use translators if necessary and confirm details in writing.

Differences in Quality Standards

Ensure both parties agree on quality standards from the outset. Regular inspections and clear communication help align expectations.

Logistics and Shipping

Navigating customs and international shipping laws can be complex. Work with experienced logistics providers to streamline this process.

The Importance of Follow-Up

After completing the project, follow up with your manufacturer. Providing feedback helps improve ongoing relationships and can enhance future collaborations.

Conclusion

Navigating the process of purchasing low volume injection molding and precise injection molding from China can seem daunting. However, with clear communication, diligence in research, and a focus on quality, businesses can successfully benefit from China’s unparalleled manufacturing capabilities. By following the steps and tips outlined in this guide, you can ensure a smooth and successful transaction.

SEO Optimized Titles and Meta Descriptions

- Titles:

- Low Volume Injection Molding: Buying from China

- Precise Injection Molding: A Guide to China Suppliers

- How to Source Injection Molding in China

- Buying Low Volume Molding Services from China

- Get Precise Injection Molding from China

- China’s Injection Molding Benefits Explained

- Step-by-Step: Purchasing Injection Molding

- Navigating China’s Injection Molding Market

- Low Volume and Precise Molding: China Guide

- Mastering Injection Molding Purchases in China

- Meta Descriptions:

- Discover how to buy low volume injection molding from China effectively and affordably.

- Learn about navigating China’s precise injection molding market for your business needs.

- Explore the benefits and steps to sourcing low volume injection molding in China.

- Find out how precise injection molding services from China can enhance your production.