China has established itself as a global leader in the manufacturing industry, known for its advanced capabilities, cost efficiency, and innovation. Among its many specialties, CNC (Computer Numerical Control) machining stands out as a crucial aspect of China’s industrial landscape. CNC machining in China is a go-to solution for industries worldwide, providing high-quality precision parts for various sectors, including automotive, aerospace, electronics, and healthcare. In this article, we will explore why CNC machining in China is so popular, its benefits, key industries served, and what to consider when choosing a CNC machining supplier in China.

Why Choose CNC Machining in China?

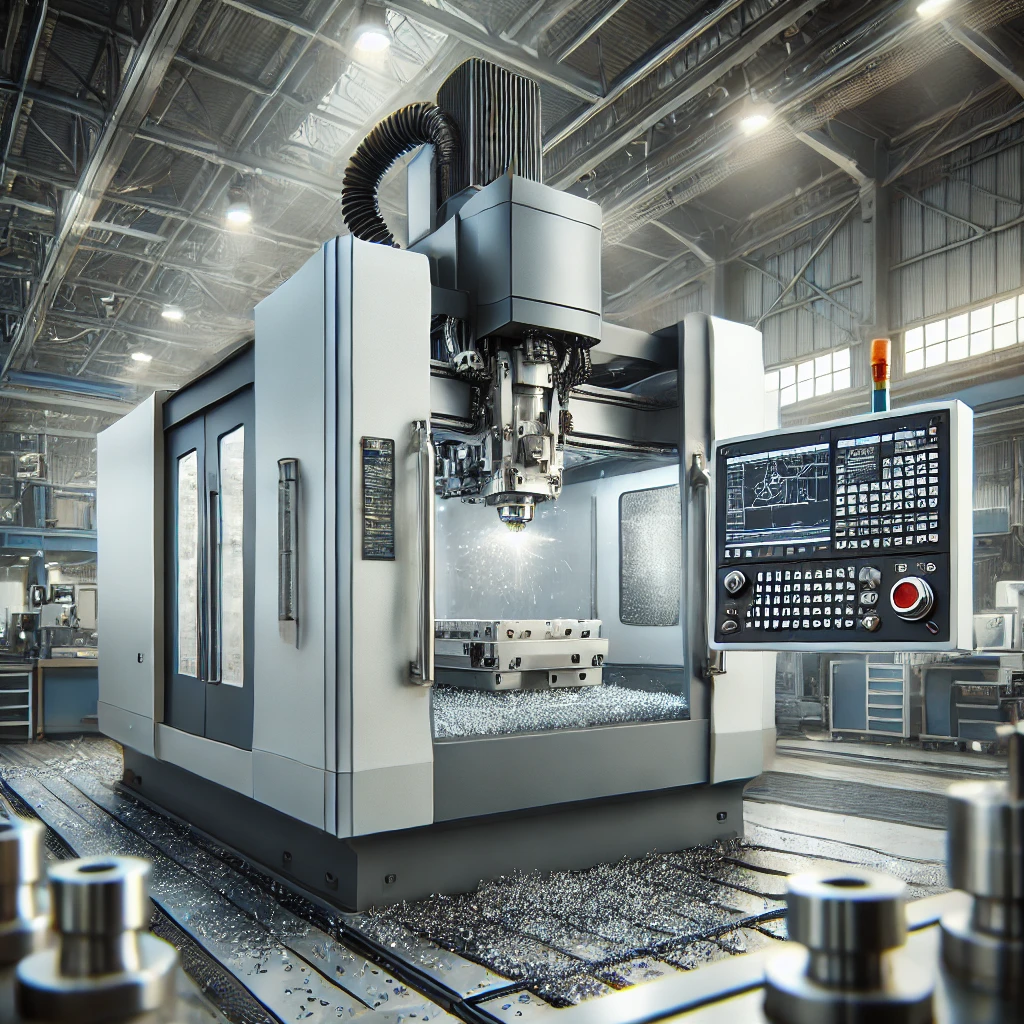

CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools. The technology offers high precision, consistent quality, and the ability to produce complex parts with tight tolerances. China’s prominence in CNC machining is attributed to several factors:

Cost-Effectiveness: China offers competitive pricing for CNC machining services due to lower labor costs, streamlined supply chains, and high production capacity.

Advanced Technology: Chinese manufacturers have invested heavily in the latest CNC technology, including 5-axis CNC machines, multi-axis turning centers, and precision grinders.

Skilled Workforce: The country has a vast pool of skilled technicians and engineers with extensive experience in CNC machining, ensuring high-quality production standards.

Scalability and Flexibility: Chinese CNC machining companies can handle projects of any scale, from prototype production to high-volume manufacturing, making them ideal partners for companies of all sizes.

Comprehensive Supply Chain: China’s well-developed supply chain ecosystem supports CNC machining with readily available raw materials, rapid prototyping, and various finishing services.

Benefits of CNC Machining in China

High Precision and Quality: With modern CNC machines and stringent quality control processes, Chinese manufacturers can achieve precise tolerances and produce parts that meet international standards.

Short Lead Times: The efficient production capabilities and quick turnaround times in China make it an attractive destination for companies looking to reduce their product development cycles.

Cost Efficiency: Compared to other manufacturing hubs, CNC machining in China offers a cost advantage without compromising quality, thanks to optimized production processes and economies of scale.

Customization Options: Chinese CNC machining suppliers are known for their ability to offer custom machining solutions, including unique part geometries, special materials, and intricate designs.

Full Range of Services: From milling and turning to drilling, grinding, and surface finishing, Chinese CNC machining companies provide a one-stop solution for all machining needs.

Key Industries Served by CNC Machining in China

Automotive: China’s CNC machining services play a pivotal role in producing engine components, transmission parts, and custom automotive accessories.

Aerospace: High-precision aerospace components such as turbine blades, engine parts, and structural elements are produced using advanced CNC machines in compliance with stringent industry standards.

Electronics: cnc machining china is widely used for producing electronic enclosures, heat sinks, and intricate parts required for various consumer electronics and communication devices.

Healthcare: Medical device manufacturing relies on CNC machining for producing surgical instruments, implants, and other components with high precision and hygiene standards.

Industrial Equipment: Chinese CNC machining services cater to industrial machinery, providing custom components that meet rigorous performance and durability requirements.

How to Choose a CNC Machining Supplier in China

When selecting a CNC machining supplier in China, it is essential to consider several factors to ensure you receive high-quality parts and reliable services:

Experience and Capabilities: Look for companies with a proven track record in CNC machining, experienced technicians, and state-of-the-art machinery.

Certifications: Verify that the supplier holds relevant certifications, such as ISO 9001, ISO 13485, or AS9100, to ensure adherence to quality standards.

Material and Process Expertise: Choose a supplier with expertise in working with a wide range of materials, including metals (aluminum, steel, titanium) and plastics (ABS, POM, PTFE).

Quality Control: Ensure the supplier has a robust quality control process, including in-process inspections, CMM (Coordinate Measuring Machine) testing, and final product verification.

Communication and Support: Effective communication is crucial when working with international suppliers. Choose a company that offers excellent customer support, clear communication, and flexible logistics options.

Conclusion

CNC machining in China has become a cornerstone of global manufacturing due to its high precision, cost efficiency, and advanced capabilities. With a strong focus on quality and innovation, Chinese CNC machining companies cater to a diverse range of industries, providing comprehensive solutions for custom part manufacturing. Whether you are looking for rapid prototyping, small batch production, or large-scale manufacturing, China’s CNC machining services offer the expertise and reliability to meet your business needs.